Aiways works with partners in Europe to ensure end-of-life vehicles and batteries are taken back and recycled in accordance with the law

Always working with partners in Europe to ensure end-of-life vehicles and batteries are taken back and recycled in accordance with the law.

Aiways, the Shanghai start-up, focuses primarily on sustainability. It goes far beyond vehicles, but forms a cycle from development, to production, to the product life cycle and to recycling.

The Chinese market currently offers the best environment for the production of battery electric vehicles. Nowhere else in the world can production take place more locally and with shorter supply chains. Added to this is the innovative Aiways production site, which was built in cooperation with Siemens in accordance with Industry 4.0 standards and is one of the most modern vehicle production sites in the world.

All process steps have been developed and optimized with a view to environmental compatibility and the conservation of resources. From handling chemicals in the paint process to treating wastewater and optimizing frequency in the plant’s internal power grid, all possible savings have been aligned with the company’s “blue and green” strategy. the company. “Blue” for advanced technology and “Green” for low CO2 emissions.

Aiways also goes further in the use of renewable energies. For example, Aiways smart factory solar thermal system has an average daily production of 130,000 liters of hot water, which is heated to 48°C and used not only in the production process but also in buildings. administrative.

In addition, there is a photovoltaic system with an annual output of 16 megawatt hours, which is equivalent to the initial charge of more than 250,000 Aiways U5 SUVs and Aiways U6 SUV-Coupés.

The best possible customer support at every stage of the vehicle lifecycle

In addition to innovative sales models and direct customer contact, Aiways also stands for the best possible support beyond the vehicle life cycle. In Europe in particular, battery-powered products are subject to strict control and monitoring, especially electric cars.

Dr Alexandre Klose, The Executive Vice President of Overseas Operations at Aiways, said:

In collaboration with strong partners, Aiways therefore guarantees at all times the implementation of and compliance with applicable standards and laws.

“This applies not only to the trade-in of end-of-life vehicles, but also to damaged batteries in crashed vehicles,” says Dr. Alexander Klose, Executive Vice President of Overseas Operations at Aiways, explaining the range. of services offered by PRIOREC recycler vehicle, with whom the company has concluded a cooperation agreement for the German market.

The second chance outside the car: Second Life as sustainable reuse of high-quality drive components

In addition to the cooperation with PRIOREC in Germany, there is another cooperation with Green Vision in France, which is currently in the test phase. The company, which has ten years of experience in this field, specializes in the second-life use of high-voltage components in the automotive industry and not only uses the traction batteries, but also uses the motors for various applications. .

Four former Aiways U5 SUV pre-series test vehicles have been handed over to Green Vision for this purpose and will now be used as test vehicles for various Second Life projects.

On the one hand, it is about creating electrical energy storage systems (ESS) from the high-voltage battery, which can be used, for example, to buffer renewable energies, to increase the degree of self-sufficiency of photovoltaic systems or to stabilize the grid. The second further use is for the 150 kilowatt drive motor, which will be used in electric-powered pleasure craft in the future.

Clever design of drive components as the key to optimal recycling

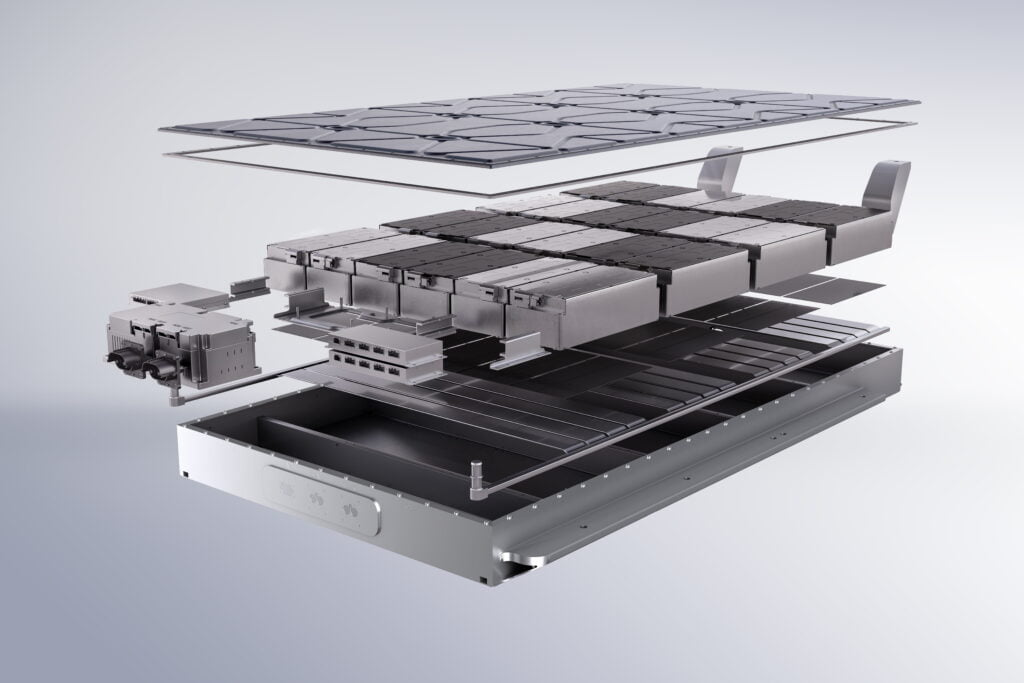

The reuse of battery vehicle components is nothing new. However, the advantage of the Aiways MAS platform for Second Life applications lies in the modularity of the components.

Yann Lelongfounder of Green Vision, said:

The sandwich structure of the battery in particular is perfect for recycling.

“You can remove the entire battery without much effort, and you can easily and quickly remove the individual modules, thanks to the innovative structure of the Aiways design.”

The advantages also apply to the drive unit, which combines motor, inverter, gearbox and control unit in one housing. This means that the compact yet powerful component can be used directly in other applications, such as the sports boat tested by Green Vision.

Thanks to the second life of essential drive components, the resource utilization of the materials used in Aiways vehicles can again be significantly improved, which ultimately leads to a sustainable cycle. Aiways would like to research and develop even more intensively in this direction in the future and is open to requests for cooperation on this topic.

Strong points:

- Environmentally friendly recycling: Aiways works with strong partners across Europe to ensure that end-of-life vehicles and batteries are taken back and recycled in accordance with the law, even in the case of damaged vehicles

- Clever design: many parts of the high-voltage battery and electric drive system are modular and can be easily recycled

- Sustainable recycling: Drive technology and high-voltage components from Aiways are used in a pilot project with “Green Vision” in battery-powered energy storage systems and in boats with no local emissions

LILY the latest Batteries News shaping the battery market

Rethinking recycling: Aiways with strong partners on the topic of “Second Life”, Shanghai/Munich, October 27, 2022

Comments are closed.